Double Wobble Pulse Laser Cleaning Machine

The Double Wobble Pulse Laser Cleaning Machine offers efficient, chemical-free cleaning with dual-wobble laser heads, ideal for rust, coating, and residue removal.

$4,300 – $16,000

| Model | MC-100 | MC-200 | MC-300 |

| Laser Power | 100W | 200W | 300W |

| Laser Type | Fiber Laser | ||

| Laser Generator | JPT | ||

| Power Stability | ±5% | ||

| Central Wavelength | 1064nm | ||

| Laser Mode | Pulse Wave | ||

| Scan Width | 0-180mm | ||

| Laser Adjustment | 10%-100% Adjustable | ||

| Fiber Cable Length | 3m-5m | ||

| Cooling Type | Air Cooling | ||

| Working Environment | Temperature Range: 5~35℃; Humidity Range: 5%~75% | ||

The Double Wobble Pulse Laser Cleaning Machine features a high-performance laser generator, delivering precise and powerful pulses for efficient cleaning. Engineered for durability, it ensures consistent output and reliable performance in various applications, enhancing productivity and effectiveness.

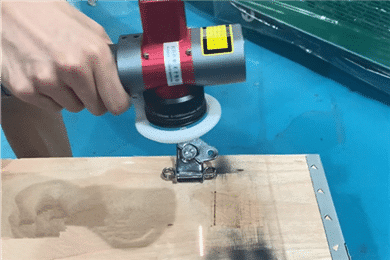

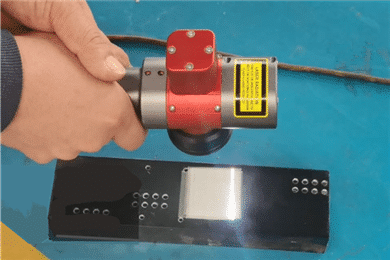

Advanced laser cleaning gun with a dual-wobble mechanism offer superior efficiency and coverage. Their ergonomic design ensures ease of use and durability, handling both large-scale and detailed cleaning tasks with precision.

The Double Wobble Pulse Laser Cleaning Machine is equipped with a robust air cooling system. This ensures optimal thermal management, enhancing performance and extending the equipment’s lifespan.

The advanced control system allows intuitive management of laser intensity and modes. Real-time monitoring and diagnostics provide precise operation and performance feedback, boosting efficiency and reliability across different applications.

The protective glasses feature specialized filters to block harmful laser radiation, ensuring operator safety. Ergonomically designed for comfort and clarity, they protect against laser beams and debris while meeting industry safety standards.

| Cleaning Method | Double Wobble Pulse Laser Cleaning | Chemical Cleaning | Mechanical Cleaning | Ultrasonic Cleaning |

| Effectiveness | Highly effective with dual-wobble heads for thorough removal of rust, coatings, and contaminants. | Effective on a range of surfaces but may leave residues. | Effective for heavy debris and dirt. | Highly effective for intricate parts. |

| Precision | Very precise, ideal for delicate and complex surfaces. | Variable, depends on application and surface. | Less precise, may cause damage to surfaces. | Very precise, suitable for delicate items. |

| Surface Damage | Minimal surface damage when properly used. | Potential for surface damage or corrosion. | Higher risk of scratching or damaging surfaces. | Minimal damage if used correctly. |

| Environmentally Friendly | Eco-friendly, no chemicals used, minimal waste. | Often involves hazardous chemicals. | May generate debris and dust. | Generally eco-friendly, no chemicals used. |

| Operating Cost | Low ongoing costs, minimal consumables. | Ongoing cost for chemicals. | Initial equipment cost, maintenance required. | Higher initial cost, maintenance required. |

| Operational Safety | Safe with proper training, low risk of hazardous exposure. | Safety concerns with chemical handling. | Risk of injury from mechanical parts. | Safe with appropriate handling. |

| Ease of Use | User-friendly, requires minimal setup. | Requires handling and disposal of chemicals. | Requires physical effort and may need specialized training. | Requires equipment setup and maintenance. |

| Maintenance Requirements | Low maintenance with periodic cleaning of laser optics. | Regular disposal and handling of chemicals. | Regular equipment maintenance is needed. | Regular maintenance of ultrasonic equipment. |

| Versatility | Highly versatile, suitable for a wide range of materials and conditions. | Less versatile, specific to certain chemicals and surfaces. | Limited to physical surface types. | Versatile for specific cleaning needs but limited to certain applications. |

| Cleaning Speed | Fast and efficient for most applications. | Variable, often slower due to chemical dwell times. | Effective but may take longer for detailed work. | Fast for small and detailed items. |

Maxcool CNC is committed to integrating the latest technological advancements into our machines. Our laser cleaning machines feature precise control, high efficiency, and superior performance, ensuring optimal cleaning results for various industrial applications.

Our machines are built to last, with robust construction and high-quality components that guarantee long-term reliability and minimal maintenance. You can trust Maxcool CNC to provide equipment that withstands even the toughest environments.

From pre-sales consultation to after-sales technical assistance, we are with you every step of the way. Our dedicated support team ensures you have all the information and help you need to maximize the value of your investment.

Maxcool CNC’s laser cleaning machines are designed with energy efficiency in mind, reducing power consumption without compromising performance. This not only lowers operational costs but also contributes to a more sustainable future.

4 reviews for Double Wobble Pulse Laser Cleaning Machine

Ava White –

We use this in our factory for routine cleaning, and it’s made a huge difference in productivity.

Ethan King –

Perfect for our automotive workshop! It cleaned engine parts without any need for harmful chemicals.

Christopher Thompson –

The power and precision of this machine are remarkable. Rust and paint come off effortlessly.

Mia Lewis –

It’s simple to use and gives professional results. Our machines look brand new again.