| Feature |

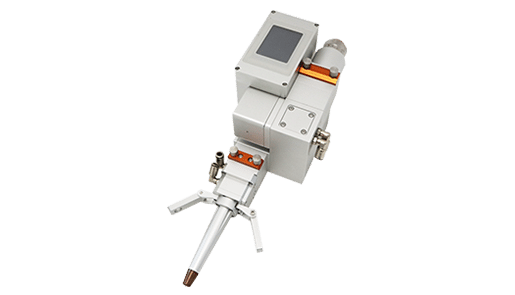

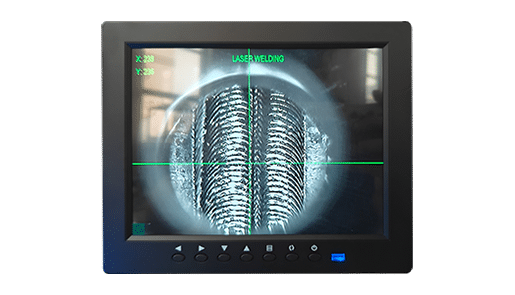

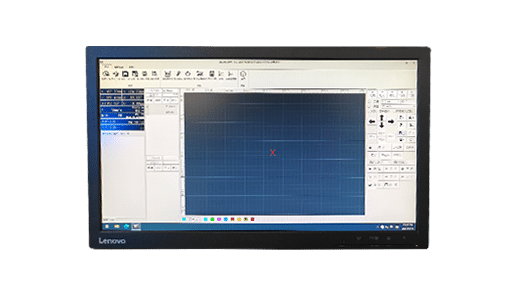

CNC Platform Automatic Laser Welding |

TIG Welding |

MIG Welding |

Stick Welding |

| Operate Mode |

Automatic welding |

Manual welding |

Manual welding |

Manual welding |

| Welding Speed |

High speed and efficiency |

Slower, highly precise |

Faster than TIG, but less precise |

Moderate speed varies with skill |

| Precision |

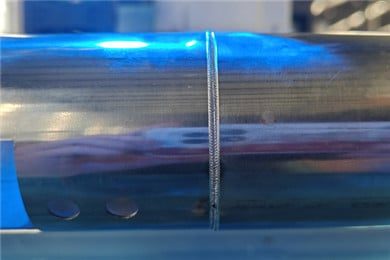

High precision with a double wobble mechanism |

Very precise, suitable for thin materials |

Good precision, less than laser |

Lower precision, more suitable for thick materials |

| Heat Affected Zone |

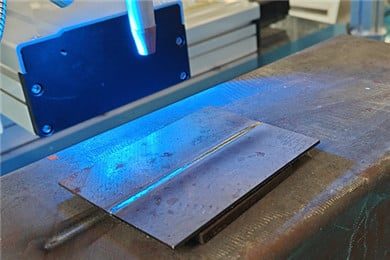

Minimal heat affected zone |

Larger, potential for warping |

Moderate heat affected zone |

Larger, can cause significant warping |

| Material Versatility |

Effective for various metals and alloys |

Excellent for thin and high-quality metals |

Versatile, suitable for various materials |

Limited to certain materials and thicknesses |

| Post-Weld Cleanup |

Minimal, clean welds |

Requires cleanup and finishing |

Moderate, depending on weld quality |

Significant cleanup is needed, and more spatter |

| Operational Cost |

Generally higher initial cost, low running costs |

Moderate equipment cost, consumables needed |

Lower initial cost, higher consumables cost |

Lower initial cost, high consumables, and maintenance cost |

| Skill Level Required |

Requires specialized training |

High skill level needed for best results |

Moderate skill level, easier to learn |

Requires significant skill and experience |

| Safety |

Requires proper eye protection and safety measures |

Requires safety gear to protect from UV and heat |

Requires safety gear to protect from spatter and UV |

Requires protective gear and careful handling |

4 reviews for CNC Platform Automatic Fiber Laser Welding Machine

Sophie Reed –

This machine is powerful yet easy to control. I’m impressed with the precision and consistency of the welds.

Jason Stewart –

One of the most reliable welding machines I’ve used. The precision is remarkable, and it’s extremely user-friendly.

Luna Long –

I’ve been using this machine for several projects, and it hasn’t disappointed me once. It’s reliable and delivers high-quality welds.

Aaron Barnes –

The laser welding machine is perfect for my custom metal fabrication shop. It’s fast and delivers excellent results.