Introduction to Laser Welding Machine

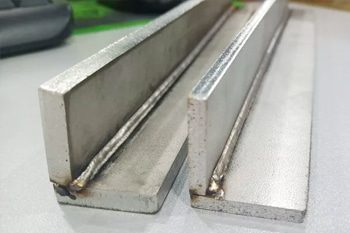

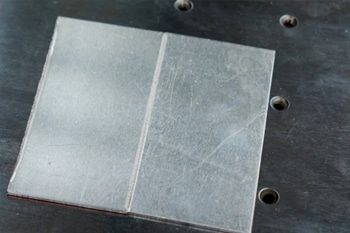

Laser welding machines are highly efficient tools that use concentrated laser beams to join materials. The working principle of a laser welding machine involves directing a focused laser beam onto the material’s surface, which rapidly heats and melts it. Once the laser is removed, the molten area cools and solidifies, forming a strong weld. Laser welding is known for its precision, speed, and ability to produce clean, high-quality welds with minimal heat-affected zones, making it ideal for delicate or complex tasks. Maxcool CNC’s laser welding machines are designed to handle a wide range of materials, including stainless steel, aluminum, carbon steel, and other alloys. They offer exceptional accuracy due to the concentrated heat of the laser, reducing the need for post-weld finishing and lowering distortion in the material.

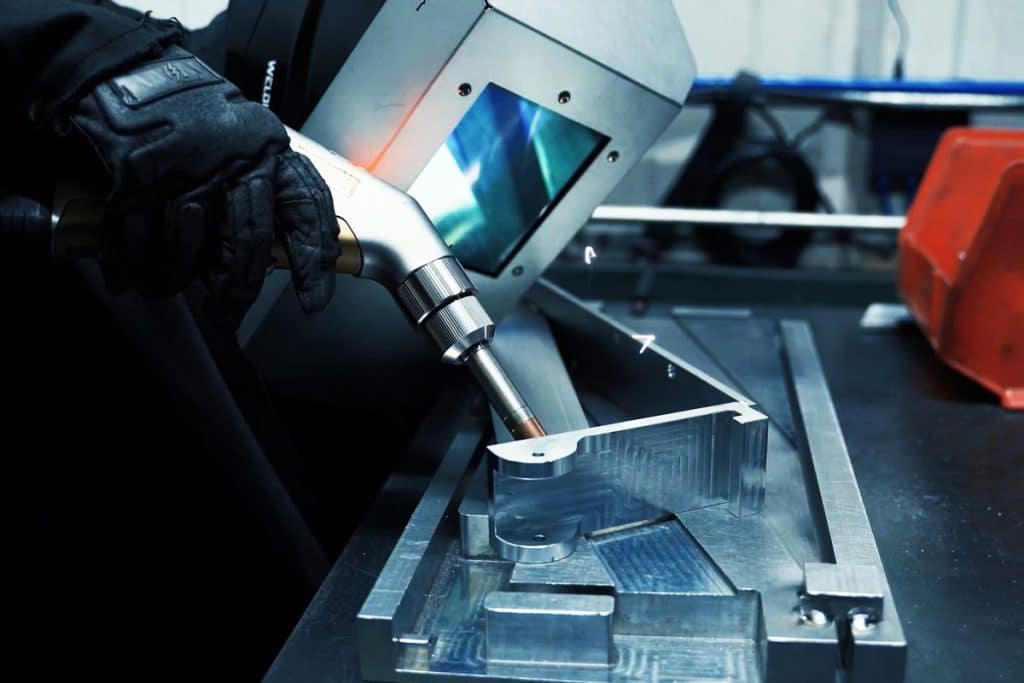

Equipped with advanced control systems and high-power laser generators, Maxcool’s laser welding machines can be used in manual or automated processes. They are particularly suited for applications requiring precision and cleanliness, such as automotive, aerospace, electronics, and medical industries. With user-friendly interfaces and adjustable parameters, these machines ensure versatility and high performance across different welding projects.

Laser Welding Machines

Maxcool CNC’s laser welding machines are designed with cutting-edge configurations to ensure high performance and precision. These machines feature a high-power fiber laser generator, which delivers excellent stability and efficiency, making them suitable for welding a variety of metals such as stainless steel, aluminum, and copper. The machines are equipped with a handheld or automated laser welding head, offering flexibility for both manual operations and industrial-scale automation.

To maintain optimal performance, Maxcool CNC laser welding machines are integrated with an advanced cooling system, ensuring continuous operation without overheating. The machines also include a user-friendly control system, allowing operators to easily adjust laser parameters like power, speed, and focus for precise welding results.

Comparison Between Handheld and Automatic Laser Welding Machines

| Feature | Handheld Laser Welding Machine | Automatic Laser Welding Machine |

| Flexibility | High mobility, suitable for complex or irregular parts | Fixed, suitable for repetitive or large-scale tasks |

| Ease of Use | Requires manual operation, more control by the user | Fully automated, requires programming and setup |

| Welding Speed | Moderate speed, dependent on operator skill | High speed, consistent output with programmed paths |

| Precision | Good precision but operator-dependent | High precision, ideal for tight tolerances |

| Applications | Best for small to medium-scale jobs or custom welding tasks | Best for high-volume production or industrial automation |

| Cost | Lower initial cost, suitable for small businesses | Higher cost due to automation and programming needs |

| Maintenance | Lower maintenance, fewer components to manage | Higher maintenance, more complex systems |

| Operator Skill Requirement | Requires a skilled operator for consistent quality | Less operator intervention relies on programming |

| Material Compatibility | Suitable for various metals, similar to automatic machines | Suitable for a wide range of metals, like handheld |

| Work Environment | Can be used in various settings, more versatile | Requires a controlled environment for automation |

Applications of Laser Welding Machines

Laser welding machines from Maxcool CNC are versatile tools used across a wide range of industries due to their precision, efficiency, and ability to work with various materials. In the automotive industry, laser welding is used for creating high-strength welds in car bodies, chassis, and engine components. Its ability to minimize heat-affected zones ensures less distortion, which is critical for lightweight materials like aluminum. In the aerospace sector, laser welding machines are employed to join complex components in aircraft and spacecraft, where precision and structural integrity are essential. These machines are ideal for welding thin materials with high accuracy.

In electronics manufacturing, laser welding is used for connecting small, intricate parts, such as sensors, batteries, and connectors, where traditional welding methods may cause damage due to excessive heat. Its precision is also valuable in medical device production, ensuring high-quality, contamination-free joints in surgical instruments and implants. Furthermore, industries like jewelry making, shipbuilding, and general manufacturing benefit from laser welding machines for their versatility in handling both small and large-scale projects, offering clean, durable welds with minimal finishing work required. Maxcool CNC’s laser welding machines provide high-quality results in each of these demanding applications.

Customer Reviews

Maxcool CNC’s laser welding machine has revolutionized our production line. The precision and speed it offers are unmatched. We've been able to improve our weld quality significantly while reducing waste and downtime. It's easy to operate, and the results speak for themselves.

John PetersonManufacturing Supervisor

We chose Maxcool CNC for their reliable laser welding solutions, and we couldn’t be happier. The handheld welding machine is perfect for our custom projects, and its flexibility has allowed us to take on more diverse jobs. It's also cost-effective, making it a great investment for our business.

Emily WhiteOperations Manager

The automated laser welding machine from Maxcool CNC has streamlined our operations. We’ve seen a boost in efficiency and accuracy in our high-volume production. The machine’s intuitive controls and consistent weld quality have made a noticeable difference in our output.

Michael DavisProduction Engineer

Maxcool CNC’s laser welding machines are reliable and user-friendly. We use them for intricate tasks that require clean, precise welds, and they always deliver. The after-sales support is excellent too, and we know we can count on Maxcool CNC for any technical assistance.

Sarah JohnsonFabrication Specialist

As a small business, we needed a machine that could handle a wide range of jobs without being overly complicated or expensive. Maxcool CNC’s handheld laser welding machine was the perfect solution. It’s easy to use, and the welds are flawless every time. I highly recommend it to anyone looking for a quality machine.

David LeeWorkshop Owner

Related Resources

How To Maintain Laser Welding Machines

This article is a comprehensive guide explaining the basic methods for maintaining a stable, efficient, and reliable laser welding machine through daily, weekly, and long-term maintenance.

Power Requirements For Laser Welding Machines

This article explains the electrical power requirements of fiber laser welding machines, covering energy consumption, efficiency, cooling systems, and installation planning.

What Precautions Should Be Taken When Laser Welding?

This article is a comprehensive guide outlining the necessary safety measures, equipment considerations, and best practices to ensure safe and efficient laser welding operations.

Frequently Asked Questions

What materials can Maxcool CNC’s laser welding machines work with?

Maxcool CNC’s laser welding machines are compatible with a wide range of metals, including stainless steel, aluminum, brass, copper, and various alloys. These machines can also weld dissimilar materials, making them versatile for different industrial applications.

What is the difference between handheld and automatic laser welding machines?

Handheld laser welding machines offer flexibility for custom or small-scale projects, allowing the operator to move freely and weld irregular or complex shapes. Automatic laser welding machines, on the other hand, are designed for large-scale, repetitive tasks where precision and speed are critical. They require programming but offer higher consistency and efficiency in production environments.

How does laser welding compare to traditional welding methods?

Laser welding offers several advantages over traditional methods, including higher precision, faster welding speeds, minimal heat-affected zones, and cleaner welds that often require less post-processing. This makes it ideal for high-quality, high-speed production with less material distortion.

What are the power requirements for Maxcool CNC’s laser welding machines?

Power requirements vary depending on the model and the specific application. Maxcool CNC’s machines are designed to be energy-efficient, with options ranging from lower-power handheld models to higher-power automatic machines for industrial use. Specific power details can be provided based on the chosen configuration.

How difficult is it to operate Maxcool CNC’s laser welding machines?

Maxcool CNC’s laser welding machines are designed with user-friendliness in mind. Both handheld and automatic models come with intuitive control systems that allow easy adjustments of parameters like laser intensity, speed, and focus. Minimal training is required to operate the machines effectively, especially with the support provided by Maxcool CNC.

Do Maxcool CNC’s laser welding machines come with safety features?

Yes, all Maxcool CNC laser welding machines are equipped with safety features, including interlock systems, emergency stop buttons, and protective enclosures where necessary. These features ensure safe operation and reduce the risk of accidents in the workplace.

What industries are Maxcool CNC’s laser welding machines suitable for?

Maxcool CNC’s laser welding machines are used in various industries, including automotive, aerospace, electronics, medical device manufacturing, jewelry making, shipbuilding, and general manufacturing. Their versatility allows them to be applied in both small-scale workshops and large industrial settings.

What kind of maintenance is required for Maxcool CNC’s laser welding machines?

Maxcool CNC’s machines are designed for durability and require minimal maintenance. Regular maintenance involves cleaning the optics, checking the cooling system, and ensuring the laser head and components are free from debris. Maxcool CNC offers comprehensive maintenance guides and support services to keep the machines running efficiently.

Get Laser Welding Solutions

Maxcool CNC offers cutting-edge laser welding solutions designed to meet the demands of modern manufacturing. Our high-performance laser welding machines deliver precise, strong welds across a wide range of materials, helping you achieve superior quality and efficiency. Whether you need handheld systems or fully automated setups, our team will work closely with you to understand your specific requirements and recommend the perfect solution. Reach out today to explore how our laser welding solutions can elevate your production process.

By submitting your information, you’re taking the first step towards a partnership that redefines what’s possible in laser welding. Our team will promptly reach out to discuss your unique requirements and guide you through the journey of enhancing your manufacturing capabilities with Maxcool CNC’s laser welding solutions.