Laser Welding Zinc-Coated Steels

Zinc-Coated Steel Laser Welding Machine

-

Handheld Standard Laser Welding Machine

Rated 4.75 out of 5$3,200 – $6,600 This product has multiple variants. The options may be chosen on the product page -

Handheld Portable Laser Welding Machine

Rated 4.75 out of 5$3,100 – $6,500 This product has multiple variants. The options may be chosen on the product page -

Handheld 3 in 1 Laser Welding Cleaning Machine

Rated 5.00 out of 5$3,200 – $6,600 This product has multiple variants. The options may be chosen on the product page -

Handheld Air-Cooled Reci Laser Welding Machine

Rated 4.75 out of 5$4,300 – $5,700 This product has multiple variants. The options may be chosen on the product page -

Handheld Double Wobble Laser Welding Machine

Rated 4.75 out of 5$3,700 – $7,100 This product has multiple variants. The options may be chosen on the product page -

Handheld Double Wire Feed Laser Welding Machine

Rated 4.75 out of 5$6,200 – $6,900 This product has multiple variants. The options may be chosen on the product page -

Portable Air-Cooled Laser Welding Machine

Rated 4.50 out of 5$4,500 – $6,400 This product has multiple variants. The options may be chosen on the product page -

Handheld Air-Cooled 3 in 1 Laser Welding Machine

Rated 5.00 out of 5$4,500 – $6,400 This product has multiple variants. The options may be chosen on the product page -

CNC Platform Automatic Fiber Laser Welding Machine

Rated 4.50 out of 5$8,500 – $12,200 This product has multiple variants. The options may be chosen on the product page -

6-Axis Robotic Automatic Laser Welding Machine

Rated 5.00 out of 5$12,200 – $15,600 This product has multiple variants. The options may be chosen on the product page

Benefits of Laser Welding Zinc-Coated Steels

Reduced Heat-Affected Zone

Laser welding provides precise heat input, minimizing the heat-affected zone, which reduces distortion and ensures better preservation of the zinc coating.

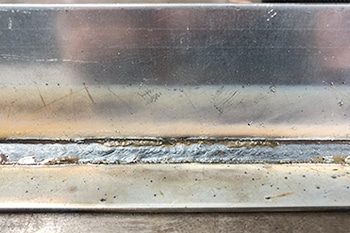

Improved Weld Quality

The focused laser energy allows for smooth, consistent welds, preventing defects such as porosity and spatter that are common when welding zinc-coated materials.

Increased Production Speed

Laser welding offers high processing speeds, reducing production time while maintaining the quality of the weld, making it ideal for high-volume applications.

Minimal Post-Weld Cleanup

With laser welding, less spatter and debris are produced, which minimizes the need for extensive post-weld cleaning and improves overall efficiency.

Enhanced Precision

The ability to precisely control the laser beam allows for accurate welding, even in complex geometries, reducing errors and ensuring strong, reliable joints.

Cost-Effective Process

By reducing material waste, post-weld cleaning time, and defects, laser welding zinc-coated steels helps lower overall production costs in both small and large-scale operations.

Factors to Consider Before Buying Zinc-Coated Steel Laser Welding Machines

Laser Power

Ensure the machine has sufficient laser power to penetrate zinc-coated steels effectively, providing strong, reliable welds without causing excess heat or damage.

Cooling System

The cooling system should efficiently dissipate heat from the laser generator to maintain consistent performance and prevent overheating, crucial for high-power welding applications.

Welding Speed

Evaluate the machine’s welding speed to match your production requirements. Faster welding speeds can enhance productivity without compromising the quality of welds.

Automation Features

Consider machines with automation options such as robotic arms or programmable settings for repetitive tasks, increasing efficiency and reducing operator involvement.

Beam Quality

High beam quality ensures precise control over the heat input, reducing defects like porosity or warping and providing smoother welds on zinc-coated steel.

Adjustable Parameters

Look for machines with customizable welding settings, allowing operators to optimize parameters for different zinc-coated steel thicknesses and coating compositions.

Durability and Maintenance

Ensure the machine is built with durable components that can withstand industrial use and offer easy maintenance to minimize downtime and operational costs.

Safety Features

Check for integrated safety features like protective enclosures and emergency stop functions, ensuring safe operation during the welding process of zinc-coated steels.

Comparison with Other Zinc-Coated Steels Welding Methods

| Feature | Laser Welding | MIG Welding | TIG Welding | Resistance Spot Welding |

| Heat-Affected Zone (HAZ) | Minimal, focused heat, reducing warping | Larger HAZ, risk of warping | Moderate HAZ, controlled with precision | Larger HAZ, more distortion |

| Weld Speed | High, suitable for fast production | Moderate speed, slower than laser | Slow, time-consuming process | Fast, especially for thin materials |

| Weld Quality | Clean, precise, minimal spatter | Higher risk of spatter and porosity | High-quality, but requires skilled labor | Prone to defects with thicker materials |

| Zinc Vapor Handling | Efficient vapor escape, reducing porosity | High risk of porosity and defects | Moderate risk, careful control needed | Poor handling of zinc vapors |

| Equipment Cost | Higher upfront cost | Lower initial cost, higher long-term maintenance | Moderate cost, skilled labor required | Moderate cost, specialized machines needed |

| Production Efficiency | Very high, suitable for automated systems | Moderate, manual process or semi-automated | Low, manual process | High for large-scale production |

| Skill Requirement | Low, easy to automate | Moderate, requires skilled operator | High, requires specialized training | Low, simple operation |

| Post-Weld Cleanup | Minimal cleanup required | Significant spatter requires more cleanup | Minimal cleanup needed | Moderate cleanup is required due to splatter |

Application of Laser Welding Zinc-Coated Steels

- Automotive Industry: Laser welding zinc-coated steel is widely used in the automotive industry for assembling body panels, frames, and structural components.

- Construction and Infrastructure: Laser welding allows for the efficient assembly of steel beams, supports, and frames, ensuring strong and durable connections while maintaining the protective zinc coating, which is essential in harsh outdoor environments.

- Energy Sector: In the energy industry, laser welding is applied to build zinc-coated steel parts for wind turbines, solar panels, and other energy infrastructure.

- Electrical Enclosures and Cabinets: Laser welding is ideal for fabricating zinc-coated steel enclosures and cabinets used in electrical and electronics industries.

- Heavy Equipment Manufacturing: For heavy machinery and equipment, laser welding is utilized to join zinc-coated steel parts that require both strength and corrosion resistance.

- Transportation Industry: Laser welding is used in the production of various vehicles, from trucks to trains.