Laser Welding Copper

Copper Laser Welding Machine

-

Handheld Standard Laser Welding Machine

Rated 4.75 out of 5$3,200 – $6,600 This product has multiple variants. The options may be chosen on the product page -

Handheld Portable Laser Welding Machine

Rated 4.75 out of 5$3,100 – $6,500 This product has multiple variants. The options may be chosen on the product page -

Handheld 3 in 1 Laser Welding Cleaning Machine

Rated 5.00 out of 5$3,200 – $6,600 This product has multiple variants. The options may be chosen on the product page -

Handheld Air-Cooled Reci Laser Welding Machine

Rated 4.75 out of 5$4,300 – $5,700 This product has multiple variants. The options may be chosen on the product page -

Handheld Double Wobble Laser Welding Machine

Rated 4.75 out of 5$3,700 – $7,100 This product has multiple variants. The options may be chosen on the product page -

Handheld Double Wire Feed Laser Welding Machine

Rated 4.75 out of 5$6,200 – $6,900 This product has multiple variants. The options may be chosen on the product page -

Portable Air-Cooled Laser Welding Machine

Rated 4.50 out of 5$4,500 – $6,400 This product has multiple variants. The options may be chosen on the product page -

Handheld Air-Cooled 3 in 1 Laser Welding Machine

Rated 5.00 out of 5$4,500 – $6,400 This product has multiple variants. The options may be chosen on the product page -

CNC Platform Automatic Fiber Laser Welding Machine

Rated 4.50 out of 5$8,500 – $12,200 This product has multiple variants. The options may be chosen on the product page -

6-Axis Robotic Automatic Laser Welding Machine

Rated 5.00 out of 5$12,200 – $15,600 This product has multiple variants. The options may be chosen on the product page

Benefits of Laser Welding Copper

High Precision and Accuracy

Laser welding copper ensures precise, clean welds with minimal distortion, making it ideal for delicate applications such as electronics and aerospace components.

Minimal Heat-Affected Zone

The focused laser beam minimizes heat spread, reducing the risk of warping or compromising copper's electrical properties during the welding process.

Fast Welding Speeds

Laser welding allows for high-speed welding, significantly improving production efficiency, especially in industries requiring high-volume copper welding.

Reduced Material Waste

Laser welding produces minimal spatter and debris, ensuring that material waste is kept to a minimum, making it a cost-effective solution.

Compatibility with Various Copper Alloys

Laser welding machines can handle a wide range of copper alloys, offering versatility for manufacturers working with different materials.

Consistent Weld Quality

Maxcool CNC's laser welding technology ensures repeatable, high-quality welds with strong joint integrity, even in mass production settings.

Factors to Consider Before Buying Copper Laser Welding Machines

Power Output

Ensure the machine's laser power is suitable for the thickness and type of copper being welded, balancing efficient penetration and minimizing heat distortion.

Cooling System Efficiency

The cooling system is critical for dissipating heat from the laser generator, maintaining stable temperatures, and preventing damage to both the machine and copper material.

Machine Versatility

Choose a machine that can handle different copper alloys and varying thicknesses, offering flexibility for a range of welding projects and production needs.

Welding Speed

Faster welding speeds improve production efficiency, which is particularly important for high-volume applications, reducing overall operational time and costs.

Precision and Control

Opt for a machine with adjustable laser settings to fine-tune power, focus, and speed, ensuring high-quality, consistent welds with minimal errors or material loss.

Automation Capabilities

Machines with automation options, like robotic integration, can streamline the welding process, increasing efficiency, precision, and consistency in repetitive or large-scale operations.

Support and Maintenance

Consider the availability of technical support, training, and maintenance services to ensure smooth operations, quick issue resolution, and long-term machine reliability.

Cost Efficiency

Evaluate the initial investment and operational costs of the machine, ensuring that it delivers a good return on investment (ROI) based on production requirements.

Comparison with Other Copper Welding Methods

| Feature | Laser Welding | TIG Welding | MIG Welding | Resistance Welding |

| Precision | High precision with minimal heat distortion | Moderate precision requires a skilled operator | Moderate, suitable for larger joints | Low precision, mostly for thin materials |

| Welding Speed | Fast welding speeds | Slower, requires more time for setup | Moderate speed, suitable for large-scale | High speed for thin sheets, slower on thicker materials |

| Heat-Affected Zone (HAZ) | Minimal due to focused laser beam | Large HAZ, more risk of material warping | Moderate HAZ depends on material thickness | Small HAZ, but less precision control |

| Material Thickness | Suitable for both thin and thick copper | Best for thin to medium-thickness | Suitable for thicker materials | Ideal for thin materials |

| Automation Capability | High, easily integrated with automation | Low, mostly manual operation | Moderate, some automation possible | High, widely used in automated systems |

| Energy Efficiency | High, concentrated laser beam reduces energy waste | Low, high energy consumption | Moderate energy efficiency | High, but energy loss in high-thickness materials |

| Surface Finish | Excellent, minimal post-processing | Requires more finishing work | Moderate surface finish | Requires post-weld clean-up |

| Material Compatibility | Can weld pure copper and copper alloys | Best for pure copper, alloys can be tricky | Suitable for copper alloys | Limited compatibility with thicker copper |

Application of Laser Welding Copper

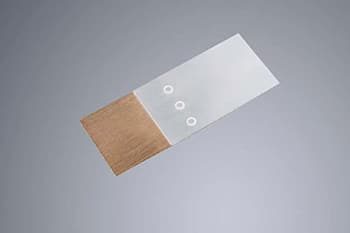

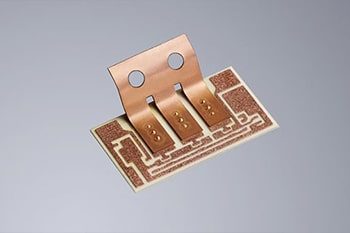

- Electronics Manufacturing: Laser welding is ideal for joining copper components like connectors, wiring, and terminals in delicate electronic devices.

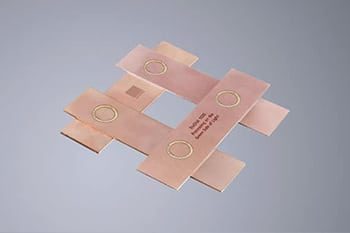

- Automotive Industry: Copper is extensively used in the automotive industry for electrical systems, including wiring harnesses, battery components, and electric vehicle (EV) parts.

- Aerospace Industry: In the aerospace sector, copper components are used in critical applications such as electrical systems and heat exchangers.

- Power Generation: Laser welding is an effective method for joining copper components in power generation equipment, such as transformers, motors, and generators.

- Telecommunications: In telecommunications, copper is crucial for its role in transmitting signals. Laser welding is used to join copper in components like cables, connectors, and antennas.

- Medical Devices: Laser welding is increasingly used in the medical industry for copper components in devices such as imaging equipment and diagnostic tools.