Introduction

Available Models

-

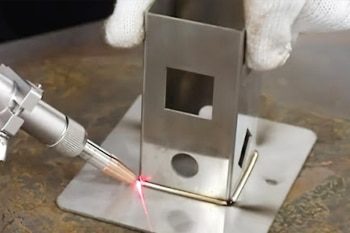

Handheld Standard Laser Welding Machine

Rated 4.75 out of 5$3,200 – $6,600 This product has multiple variants. The options may be chosen on the product page -

Handheld Portable Laser Welding Machine

Rated 4.75 out of 5$3,100 – $6,500 This product has multiple variants. The options may be chosen on the product page -

Handheld 3 in 1 Laser Welding Cleaning Machine

Rated 5.00 out of 5$3,200 – $6,600 This product has multiple variants. The options may be chosen on the product page -

Handheld Air-Cooled Reci Laser Welding Machine

Rated 4.75 out of 5$4,300 – $5,700 This product has multiple variants. The options may be chosen on the product page -

Handheld Double Wobble Laser Welding Machine

Rated 4.75 out of 5$3,700 – $7,100 This product has multiple variants. The options may be chosen on the product page -

Handheld Double Wire Feed Laser Welding Machine

Rated 4.75 out of 5$6,200 – $6,900 This product has multiple variants. The options may be chosen on the product page -

Portable Air-Cooled Laser Welding Machine

Rated 4.50 out of 5$3,400 – $5,300 This product has multiple variants. The options may be chosen on the product page -

Handheld Air-Cooled 3 in 1 Laser Welding Machine

Rated 5.00 out of 5$3,800 – $5,700 This product has multiple variants. The options may be chosen on the product page -

CNC Platform Automatic Fiber Laser Welding Machine

Rated 4.50 out of 5$8,500 – $12,200 This product has multiple variants. The options may be chosen on the product page -

6-Axis Robotic Automatic Laser Welding Machine

Rated 5.00 out of 5$12,300 – $16,000 This product has multiple variants. The options may be chosen on the product page

Application

The aluminum laser welding machine is specifically designed to handle the unique challenges of welding aluminum and its alloys, ensuring high-quality, precise welds. Key applications include:

- Automotive Industry: Ideal for welding lightweight aluminum components used in car body panels, chassis, and engine parts, offering strength and reduced weight for better fuel efficiency.

- Aerospace: Used for welding critical aluminum components in aircraft, including structural frames, fuel tanks, and engine parts, ensuring high strength and performance.

- Electronics: Perfect for welding delicate aluminum parts in consumer electronics, such as laptop casings, heat sinks, and connectors, with minimal heat distortion.

- Marine Industry: Essential for welding aluminum components in boats, ships, and marine structures, providing corrosion-resistant joints that withstand harsh environments.

- Renewable Energy: Used in the manufacturing of aluminum frames for solar panels and wind turbines, ensuring durable, efficient welds that are critical for energy production.

Welding Capabilities of Different Metals

| Material | 1000W | 1500W | 2000W | 3000W |

| Carbon Steel | 0.5-2mm | 0.5-3mm | 0.5-4mm | 0.5-5mm |

| Stainless Steel | 0.5-2mm | 0.5-3mm | 0.5-4mm | 0.5-5mm |

| Brass | 0.5-1mm | 0.5-1.5mm | 0.5-2mm | 0.5-3mm |

| 1-3 Series Aluminum Alloys | 0.5-1mm | 0.5-1.5mm | 0.5-2mm | 0.5-3mm |

| 4-7 Series Aluminum Alloys | 0.5-1mm | 0.5-1.5mm | 0.5-2mm | 0.5-3mm |

| Copper | / | 0.5mm | 0.5-1mm | 0.5-1.5mm |

- In the welding data, the core diameter of the laser output fiber is 50 microns.

- The welding data adopts a Raytools welding head (swing welding head is used for copper welding), and the optical ratio is 100/200 (collimator/focus lens focal length).

- Welding shielding gas: Argon (purity 99.99%).

- Due to the differences in equipment configuration and welding process used by different customers, this data is for reference only.

Why Choose Us

Cutting-Edge Technology

Maxcool CNC is committed to integrating the latest technological advancements into our machines. Our laser welding machines feature precise control, high efficiency, and superior performance, ensuring optimal welding results for various industrial applications.

Reliable and Durable Equipment

Our machines are built to last, with robust construction and high-quality components that guarantee long-term reliability and minimal maintenance. You can trust Maxcool CNC to provide equipment that withstands even the toughest environments.

Comprehensive Support

From pre-sales consultation to after-sales technical assistance, we are with you every step of the way. Our dedicated support team ensures you have all the information and help you need to maximize the value of your investment.

Sustainability and Efficiency

Maxcool CNC’s laser welding machines are designed with energy efficiency in mind, reducing power consumption without compromising performance. This not only lowers operational costs but also contributes to a more sustainable future.

Customer Reviews

Frequently Asked Questions

What is An Aluminum Laser Welding Machine?

Why is Laser Welding Used for Aluminum?

Can An Aluminum Laser Welding Machine Weld All Types of Aluminum Alloys?

What Are the Benefits of Using Laser Welding for Aluminum Over Traditional Welding Methods?

What Shielding Gas is Used in Aluminum Laser Welding?

Can Laser Welding be Used to Join Aluminum with Other Metals?

Related Resources

Comprehensive Guide to Laser Welding Machines

This comprehensive guide covers the principles, advantages, applications, safety measures, and selection criteria for laser welding machines in modern manufacturing.

What Are The Common Problems of Laser Welding Machines?

This article explores the most common problems encountered with laser welding machines, from porosity and cracks to machine maintenance, and learns practical solutions to improve production results.

Laser Welding VS Arc Welding

This article compares laser welding and arc welding, exploring their principles, advantages, limitations, applications, efficiency, cost, and environmental impact.