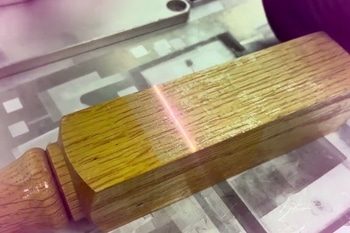

Laser Cleaning Wood

Wood Laser Cleaning Machine

-

Standard Continuous Laser Cleaning Machine

Rated 4.75 out of 5$3,200 – $6,600 This product has multiple variants. The options may be chosen on the product page -

Portable Continuous Laser Cleaning Machine

Rated 4.50 out of 5$3,100 – $6,500 This product has multiple variants. The options may be chosen on the product page -

Double Wobble Pulse Laser Cleaning Machine

Rated 4.75 out of 5$4,300 – $16,000 This product has multiple variants. The options may be chosen on the product page -

Luggage Pulse Laser Cleaning Machine

Rated 5.00 out of 5$6,300 – $16,800 This product has multiple variants. The options may be chosen on the product page -

Backpack Pulse Laser Cleaning Machine

Rated 4.75 out of 5$6,600 – $8,900 This product has multiple variants. The options may be chosen on the product page -

High Power Pulse Laser Cleaning Machine

Rated 4.75 out of 5$9,300 – $64,300 This product has multiple variants. The options may be chosen on the product page -

Double Wobble Continuous Laser Cleaning Machine

Rated 5.00 out of 5$3,700 – $7,100 This product has multiple variants. The options may be chosen on the product page

Benefits of Laser Cleaning Wood

Non-Abrasive Cleaning

Laser cleaning preserves the wood's natural texture by removing contaminants without causing surface damage, ensuring that delicate wood structures remain intact.

Eco-Friendly Process

Laser cleaning eliminates the need for harsh chemicals or solvents, making it a sustainable, environmentally friendly option that reduces waste and pollution.

Precise Control

Maxcool CNC’s laser cleaning machines offer precise control over the cleaning process, allowing operators to target specific areas without affecting surrounding wood.

No Surface Residue

Laser cleaning leaves no residue or harmful by-products, ensuring the wood is left clean and ready for immediate further processing or restoration.

Time Efficiency

The high-speed capabilities of laser cleaning significantly reduce cleaning time compared to traditional methods, increasing productivity in both restoration and industrial applications.

Minimal Maintenance

Laser cleaning machines require minimal maintenance, reducing operational costs over time while providing consistent, reliable performance for various wood-cleaning tasks.

Factors to Consider Before Buying Wood Laser Cleaning Machines

Laser Power Output

Ensure the machine provides adjustable laser power output to handle different wood types and contaminants without damaging the surface.

Surface Compatibility

Consider whether the machine can clean various wood surfaces, including treated, painted, and natural woods, while preserving their texture and integrity.

Machine Size and Portability

The machine's size and portability should align with your workspace and project needs, whether for large-scale industrial use or small, intricate restoration work.

Safety Features

Look for safety features like emergency stop buttons, protective enclosures, and interlocks to ensure a safe working environment for operators and surrounding areas.

Energy Efficiency

Choose a machine with energy-efficient designs to reduce operational costs over time, especially for high-volume cleaning tasks, while maintaining cleaning performance.

Ease of Operation

User-friendly controls and intuitive software are essential to ensure that operators can easily adjust settings and perform cleaning tasks efficiently.

Maintenance Requirements

Evaluate the machine's maintenance needs to ensure it operates reliably with minimal downtime, reducing long-term costs and increasing overall productivity.

Customer Support and Warranty

Consider the level of customer support, training, and warranty options offered by the manufacturer to ensure smooth operation and service throughout the machine's lifespan.

Comparison with Other Wood Cleaning Methods

| Feature | Laser Cleaning | Sanding | Chemical Cleaning | Pressure Washing |

| Precision | High precision, selective cleaning | Moderate, can remove fine details | Low, difficult to control application | Low, may damage wood surface |

| Environmental Impact | Eco-friendly, no chemicals used | Dust generation, no chemicals | Harmful chemicals involved | High water usage, potential runoff |

| Surface Preservation | Non-abrasive, preserves wood texture | Abrasive, can damage wood surfaces | Can cause chemical damage to wood | May cause water damage, swelling |

| Speed | Fast, especially for detailed areas | Slow for large surfaces | Moderate, depending on application | Fast for larger areas, less precise |

| Maintenance | Low, minimal maintenance required | Moderate, requires frequent sanding | High, chemical replenishment needed | Low, occasional equipment cleaning |

| Cost-Effectiveness | High initial cost, low operating cost | Low, but labor-intensive | High, recurring chemical costs | Moderate, cost of water and equipment |

| Safety | Safe, no harmful chemicals or dust | Dust may require safety equipment | Hazardous chemicals may pose risks | Risk of injury from high-pressure water |

Application of Laser Cleaning Wood

- Historical Restoration: Laser cleaning is widely used in restoring historical wooden structures and artifacts, where preserving the intricate details and natural beauty of the wood is critical. The non-abrasive method ensures minimal surface damage.

- Furniture Refinishing: Laser cleaning provides a safe and effective way to remove old paint, varnish, or dirt from furniture, allowing for quick refinishing or preparation for reapplication of new coatings.

- Art and Sculptural Woodwork: For delicate art pieces and sculptures, laser cleaning offers precise control, ensuring only the unwanted materials are removed without affecting the original design or craftsmanship.

- Wooden Facades and Architecture: Laser cleaning can be applied to architectural elements such as wooden facades, beams, and flooring, efficiently removing dirt, mold, and weathering effects, while preserving the wood’s structural integrity.

- Antique Wood Restoration: For antique dealers and collectors, laser cleaning is an invaluable tool for restoring vintage wooden items without diminishing their value or historical significance, ensuring a clean yet authentic finish.

- Pre-Treatment for Coating: Laser cleaning prepares wooden surfaces by removing contaminants, allowing better adhesion for paint, varnish, or other coatings, and enhancing the final finish quality.