Laser Cleaning Metal

Metal Laser Cleaning Machines

-

Standard Continuous Laser Cleaning Machine

Rated 4.75 out of 5$3,200 – $6,600 This product has multiple variants. The options may be chosen on the product page -

Portable Continuous Laser Cleaning Machine

Rated 4.50 out of 5$3,100 – $6,500 This product has multiple variants. The options may be chosen on the product page -

Double Wobble Pulse Laser Cleaning Machine

Rated 4.75 out of 5$4,300 – $16,000 This product has multiple variants. The options may be chosen on the product page -

Luggage Pulse Laser Cleaning Machine

Rated 5.00 out of 5$6,300 – $16,800 This product has multiple variants. The options may be chosen on the product page -

Backpack Pulse Laser Cleaning Machine

Rated 4.75 out of 5$6,600 – $8,900 This product has multiple variants. The options may be chosen on the product page -

High Power Pulse Laser Cleaning Machine

Rated 4.75 out of 5$9,300 – $64,300 This product has multiple variants. The options may be chosen on the product page -

Double Wobble Continuous Laser Cleaning Machine

Rated 5.00 out of 5$3,700 – $7,100 This product has multiple variants. The options may be chosen on the product page

Benefits of Laser Cleaning Metal

Non-Abrasive Cleaning

Laser cleaning is non-abrasive, ensuring that metal surfaces remain intact without any mechanical damage or wear, preserving the material's integrity.

Precision and Control

Laser cleaning provides exceptional precision, allowing for targeted cleaning of specific areas without affecting adjacent surfaces or components, making it ideal for detailed work.

Environmentally Friendly

This process eliminates the need for harmful chemicals and abrasive materials, reducing environmental impact and making it a cleaner, more sustainable cleaning solution.

Minimal Maintenance and Downtime

Laser cleaning requires minimal maintenance and delivers fast, consistent results, reducing downtime and increasing overall efficiency in industrial applications.

Versatility Across Metals

Laser cleaning works effectively on a wide range of metals, including stainless steel, aluminum, and brass, offering flexibility for various industrial and commercial uses.

No Secondary Waste

Unlike traditional cleaning methods, laser cleaning produces no secondary waste like debris or residue, which simplifies cleanup and reduces disposal costs.

Factors to Consider Before Buying Metal Laser Cleaning Machines

Laser Power Output

Consider the required power level for your tasks, as higher power enables faster cleaning, while lower power is ideal for delicate surfaces.

Material Compatibility

Ensure the machine is compatible with the metals you work with, as different machines may perform better on specific materials like stainless steel or aluminum.

Portability and Size

Evaluate whether you need a portable laser cleaning machine for field use or a stationary machine for in-house applications, depending on your operational setup.

Cleaning Speed

Consider the machine’s cleaning speed and efficiency, which impacts productivity, especially for larger industrial applications requiring fast, thorough cleaning.

Maintenance Requirements

Check the maintenance frequency and cost associated with the machine to ensure it’s easy to maintain and does not incur significant downtime.

Cost and Return on Investment

Assess the initial investment cost and potential long-term savings in labor, material preservation, and efficiency to calculate the overall return on investment.

Safety Features

Ensure the machine includes essential safety features such as protective enclosures, emergency stop buttons, and interlock systems for safe operation.

Environmental Impact

Laser cleaning is an eco-friendly method, but it’s important to confirm that the machine minimizes environmental impact by avoiding chemicals and producing no secondary waste.

Comparison with Other Metal Cleaning Methods

| Feature | Laser Cleaning | Sandblasting | Chemical Cleaning | Ultrasonic Cleaning |

| Material Preservation | Non-abrasive, maintains metal integrity | Abrasive, can wear down the material surface | May corrode metal over time | Non-abrasive, preserves material |

| Precision | High precision, selective cleaning of areas | Low precision, affects larger areas | Moderate precision, dependent on chemicals | High precision, especially for small parts |

| Environmental Impact | Eco-friendly, no chemicals or waste | Dust and debris generation | Requires hazardous chemicals | Eco-friendly, uses water and detergents |

| Cleaning Speed | Fast and efficient for most metals | Slower, especially for intricate surfaces | Varies based on chemical reaction times | Slower for large parts, faster for small parts |

| Versatility | Effective on a wide range of metals and contaminants | Limited to tougher surfaces | Dependent on chemical compatibility | Primarily for small, intricate components |

| Secondary Waste | No secondary waste, clean and simple | Significant waste (abrasive materials, dust) | Generates chemical waste requiring disposal | No waste, but requires water management |

| Maintenance and Operation | Low maintenance, minimal operating costs | Frequent maintenance, high wear on equipment | Regular handling of hazardous substances | Requires special tanks and handling |

| Safety | Safe with proper safeguards (protective enclosure) | Risk of flying debris, requires safety gear | Exposure to toxic chemicals | Safe, but requires proper handling |

Application of Laser Cleaning Metal

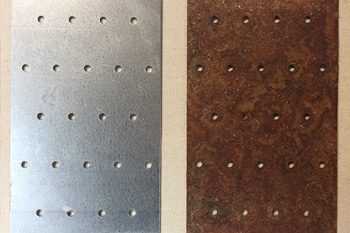

- Rust Removal: Laser cleaning effectively removes rust from metal surfaces, restoring materials to their original condition without damaging the base metal. It’s commonly used in the automotive, shipbuilding, and maintenance industries.

- Paint Stripping: Laser cleaning machines can be used to strip paint or coatings from metal surfaces, allowing for repainting or refurbishment without the need for harmful chemicals or abrasive methods.

- Weld Preparation and Cleaning: Before and after welding, laser cleaning ensures the metal surface is free of contaminants like oxides and oils, resulting in cleaner, stronger welds. This is crucial in industries like aerospace, construction, and manufacturing.

- Restoration of Historical Artifacts: Laser cleaning is delicate enough to restore metal artifacts, sculptures, and historical structures without causing any damage, making it a preferred method in the conservation and restoration fields.

- Oxide Layer Removal: Industries like electronics and energy require clean, oxide-free metal surfaces to ensure optimal electrical contact and performance. Laser cleaning provides an effective solution for this.

- Oil and Grease Cleaning: Laser cleaning machines can also remove oils, greases, and other contaminants from industrial equipment and parts, ensuring they are ready for further processing or assembly.