Introduction to Pulse Laser Cleaning Machine

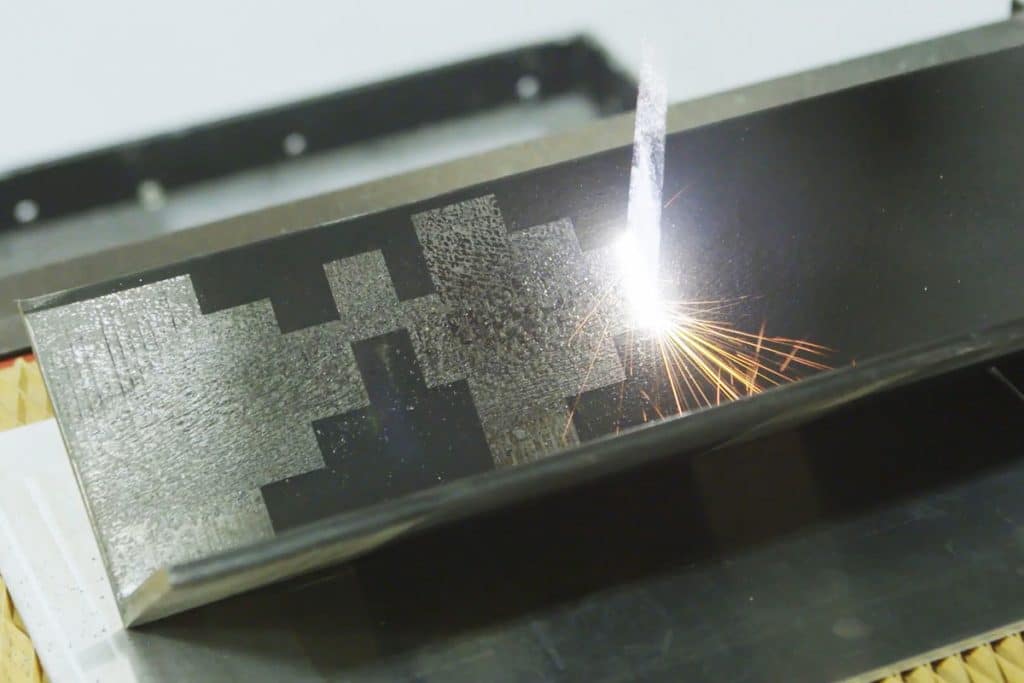

The pulse laser cleaning machine utilizes short, high-intensity laser pulses to remove contaminants, rust, paint, and other surface layers from various materials. The working principle is based on the concept of laser ablation, where the laser beam is absorbed by the target material’s surface layer, generating a rapid expansion of heat that effectively vaporizes and removes unwanted layers without damaging the substrate.

Unlike continuous laser cleaning machines, the pulse laser method offers precise control, minimizing heat impact on delicate surfaces. This makes it ideal for cleaning tasks that require high precision, such as in aerospace, automotive, and heritage conservation industries. Pulse laser cleaning is especially suitable for removing thin coatings, oxidation layers, and contaminants from metal surfaces.

Additionally, pulse laser cleaning machines are energy-efficient and offer an eco-friendly cleaning solution, eliminating the need for chemicals or abrasives. They are highly adaptable to different surface materials, providing flexibility in various industrial applications. The machine’s user-friendly interface, combined with adjustable cleaning parameters, allows for easy operation and optimal performance across diverse cleaning needs.

Pulse Laser Cleaning Machines

The pulse laser cleaning machine from Maxcool CNC is designed with advanced configuration to ensure precise and efficient cleaning. It features a high-performance pulse laser generator that delivers short, controlled bursts of energy, making it ideal for delicate surfaces. The machine comes equipped with a handheld laser cleaning head for easy maneuverability, allowing for precise targeting of contaminants, rust, and coatings.

The machine also includes an integrated cooling system to maintain optimal operating temperatures, ensuring stable and consistent performance. Its user-friendly control panel provides operators with the ability to adjust laser parameters, such as power and pulse duration, to suit various cleaning applications. In addition, the compact design and lightweight construction allow for easy transportation and setup, making it versatile for use in different environments.

Applications of Pulse Laser Cleaning Machines

The pulse laser cleaning machine from Maxcool CNC is highly versatile and used in a wide range of industrial applications. Its precise, non-contact cleaning method is ideal for industries such as aerospace, automotive, electronics, and restoration. It excels at removing rust, paint, oxides, and surface contaminants from metals without damaging the underlying material, making it suitable for delicate parts and surfaces that require careful handling.

In the aerospace industry, it is used for cleaning turbine blades and other sensitive components. The automotive sector benefits from its ability to remove coatings and residues from body panels, engine parts, and welding surfaces. Pulse laser cleaning is also widely applied in heritage conservation, where it safely removes dirt and corrosion from historical artifacts, statues, and other delicate structures.

Additionally, the machine’s adaptability makes it ideal for industries requiring high-precision cleaning, such as electronics, where it can clean circuits and delicate components without thermal damage. Its eco-friendly design, eliminating the need for chemicals and abrasive materials, makes it a sustainable solution for a variety of cleaning tasks.

Customer Reviews

The pulse laser cleaning machine has made our cleaning processes more efficient. It’s precise, easy to use, and requires no harsh chemicals. We’ve been able to extend the lifespan of our equipment with regular cleaning using this machine.

JohnMaintenance Supervisor

We use this machine to remove paint and residue from engine components, and it works flawlessly. The handheld laser cleaning head gives us the flexibility to clean even the most intricate parts without damaging them. Highly recommended!

MariaAutomotive Engineer

For our heritage conservation projects, this pulse laser cleaner is invaluable. It allows us to carefully remove layers of dirt and corrosion from historic artifacts without causing any damage. It’s a game-changer for our work.

DavidRestoration Specialist

We’ve implemented Maxcool’s pulse laser cleaning machine across several of our production lines, and the results are outstanding. It’s fast, precise, and safe for our operators. We couldn’t be happier with the performance.

LindaProduction Manager

This machine has become an essential tool in our shop. It handles the cleaning of sensitive aerospace components with incredible precision, and the results are always flawless. Maxcool has delivered a top-quality product.

RobertAerospace Technician

Related Resources

Laser Cleaning Machine Cooling System Maintenance Guide

Comprehensive guide on maintaining laser cleaning machine cooling systems, covering inspection, coolant care, troubleshooting, and best practices for reliable performance and longevity.

Laser Cleaning VS Dry Ice Blasting

Comprehensive guide comparing laser cleaning and dry ice blasting: principles, equipment, applications, speed, surface effects, safety, environmental impact, costs, and selection criteria.

Applications of Pulsed Laser Cleaning

This article explores the diverse applications of pulsed laser cleaning across industries, highlighting its principles, benefits, and impact on modern maintenance and manufacturing.

Frequently Asked Questions

What materials can the pulse laser cleaning machine remove contaminants from?

The pulse laser cleaning machine is suitable for cleaning a wide range of materials, including metals like stainless steel, aluminum, copper, and brass. It effectively removes rust, paint, oxides, oil, and other surface contaminants without damaging the underlying material.

How does pulse laser cleaning differ from continuous laser cleaning?

Pulse laser cleaning uses short bursts of high-intensity laser energy, which provides more precise control over the cleaning process. It is ideal for delicate surfaces and high-precision tasks, whereas continuous laser cleaning is better suited for larger areas and thicker contaminants due to its consistent energy output.

Is the pulse laser cleaning machine safe for delicate surfaces?

Yes, the machine is designed for precision cleaning, making it suitable for delicate surfaces. The pulse laser allows operators to adjust the power and duration of the laser to match the specific cleaning needs, ensuring no damage to sensitive materials.

What industries benefit most from using a pulse laser cleaning machine?

The machine is commonly used in industries such as aerospace, automotive, electronics, and restoration. It is highly effective for tasks requiring precise cleaning, such as removing corrosion from aerospace components, paint from automotive parts, and dirt from heritage artifacts.

What is the power range of the pulse laser cleaning machine?

Pulse laser cleaning machines come with a range of power options to suit different applications. These typically range from 100W to 1000W, allowing for both light cleaning tasks and more demanding industrial applications.

Does the machine require any consumables or chemicals for operation?

No, the pulse laser cleaning machine operates without the need for consumables like chemicals, abrasives, or solvents. It is an eco-friendly cleaning solution, using only the power of the laser to remove contaminants, making it both cost-effective and environmentally friendly.

How portable is the pulse laser cleaning machine?

The machine is designed with portability in mind. It features a lightweight and compact design, making it easy to transport and set up in different locations. It’s ideal for both stationary and mobile cleaning operations.

What maintenance does the pulse laser cleaning machine require?

The pulse laser cleaning machine is relatively low-maintenance. Regular cleaning of the optics and periodic inspection of the cooling system and laser source are recommended to ensure consistent performance. Maxcool CNC provides detailed guidelines for proper maintenance to maximize machine longevity.

Get Laser Cleaning Solutions

At Maxcool CNC, we provide innovative laser cleaning solutions tailored to your specific needs. Our advanced laser cleaning machines offer precise, non-abrasive cleaning for a variety of materials and industries. Whether you’re looking to remove rust, paint, or contaminants, our systems ensure efficient and eco-friendly results. Our team of experts is ready to help you select the right equipment for your application, offering full consultation and support throughout the process. Contact us today to discuss how our laser cleaning solutions can optimize your operations.

By submitting your information, you’re taking the first step towards a partnership that redefines what’s possible in laser cleaning. Our team will promptly reach out to discuss your unique requirements and guide you through the journey of enhancing your manufacturing capabilities with Maxcool CNC’s laser cleaning solutions.